Phone : +33 (0)2 38 34 61 95 Email : contact us Version française

PDG Plastiques will be present at CFIA RENNES from 12th to 14th March

PET PREFORMS, BOTTLES, CONTAINERS - STANDARD & SPECIFIC DEVELOPMENTS

PET - RPET PREFORMS

PRELACTIA PREFORMS

PET - RPET BOTTLES

PET WINE BOTTLES

PET - RPET CONTAINERS

CONTAINERS FROM 5 L TO 20 L

CHEMICAL INDUSTRY

WIDE RANGE OF COLORS

PDG PLASTIQUES

- Company

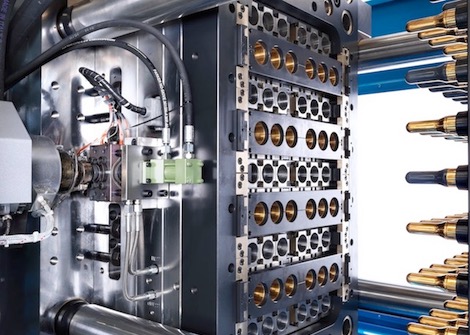

- Injection division

- Blowing division

For more than 60 years, PDG PLASTIQUES has built its know-how in the plastic packaging industry. We’re a professional team of men and women involved in an industrial adventure. PDG PLASTIQUES is an independent family business, firmly geared towards innovation, with a global performance based around 3 inseparables principles: Economic, Social and Environmental responsibility.

For more than 60 years, PDG PLASTIQUES has built its know-how in the plastic packaging industry. We’re a professional team of men and women involved in an industrial adventure. PDG PLASTIQUES is an independent family business, firmly geared towards innovation, with a global performance based around 3 inseparables principles: Economic, Social and Environmental responsibility.Present in the fields of beverages, food, health and beauty, home care and chemistry. Development of new preforms that always meet your needs. We always that our project with high confidentiality, and our engineers and technicians work in close collaboration with your teams to optimize the solutions and the delays of marketing of your packaging

The developments are from the preform conception right through to the process of your blowing machines

The developments are from the preform conception right through to the process of your blowing machines

The blowing division of PDG PLASTIQUES has produced bottles, flasks and containers in PET since 2000. A new and varied machine stock answers the needs of our customers for containers from 5 ml to 10 L.

Blowing technology (two steps) with ou without preferential heating, Injection-Blowing technology (one step), blow-trim process for wide mouth jars, complex forms, and deep grip blow molded handles.

Blowing technology (two steps) with ou without preferential heating, Injection-Blowing technology (one step), blow-trim process for wide mouth jars, complex forms, and deep grip blow molded handles.